The Railway Challenge at Sheffield team designs and builds its own 10 1⁄4 inch gauge locomotive for the Institution of Mechanical Engineers (IMechE) Railway Challenge competition. The locomotive must meet specific technical requirements set by the IMechE judges, whilst also incorporating innovations developed by the team.

The team has a great history of implementing out-of-the-box concepts. In 2017-2018 the team decided to split the locomotive into 3 separate modules, thus creating the famous "snake train". This train won the audience vote for the 'Favourite Train of the Competition'.

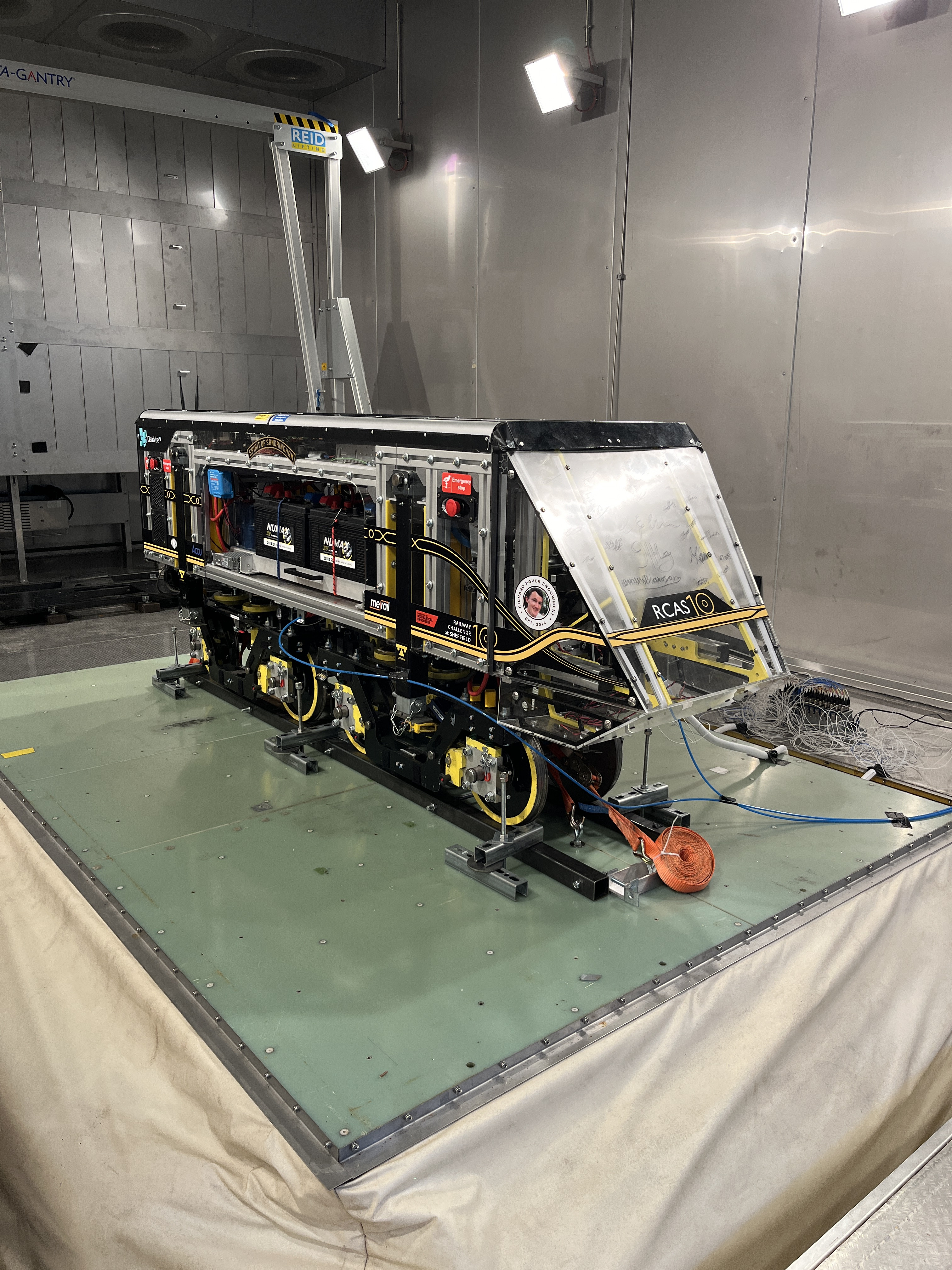

Since 2016, the canopies of their locomotives have been built using a transparent acrylic, which has been the team's trademark ever since. As a team, they think that there is nothing more interesting and educational than being able to see the inner workings of their build!

In 2018-2019 the team successfully transitioned its locomotive power source from a petrol generator to battery power. This also reduced the number of modules from 3 to 2, as the generator module had been made redundant.

In 2019-2020 the competition was cancelled due to COVID-19 and the team was not able to manufacture the locomotive. However, the team still continued and finalised the design virtually, holding virtual meetings and collaborating remotely through a variety of platforms.

From 2020-2022, the team finalised a 2 bodied, diamond-patterned locomotive. They even customised the wheels to replicate their logo.

For the 2023 competition year, the team returned to more conventional two bogie design, which despite coming 4th place scored the highest score of any RCAS locomotive up to that point.

In 2024, the design was refined, with the notable addition of a nose cone in order to compete in the aerodynamics challenge. The hard work of the team paid off, as this locomotive went on to give Sheffield it's first ever competition win!