The Alan Turing Institute is the national institute for data science and artificial intelligence, with headquarters at the British Library. It has established several Research and Innovation Cluster in Digital Twins (TRIC: DT) demonstrators. The TRIC-DT mission is to carry out fundamental research relating to digital twins that addresses the most urgent challenges facing society and achieves real-world impact. This project is one of four demonstrators with the Laboratory for Verification & Validation's (LVV) BAE T1A Hawk Jet as the key system of interest.

LVV Hawk T1A Aircraft: Digital Twin Demonstrator

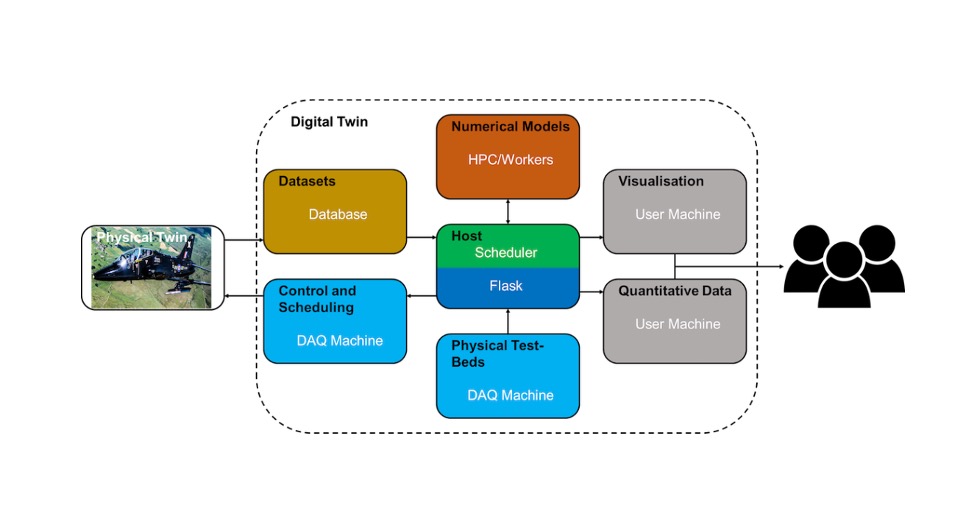

A digital twin is much more than just a numerical model: It is a virtualised proxy version of the physical system built from a fusion of data with models of differing fidelity. Digital twins use novel techniques in uncertainty analysis, model reduction, data visualisation, and experimental validation to provide useful insight.

About The Project

The purpose of this project is to demonstrate digital twin principals through the Digital Twin Operational Platform (DTOP) framework. DTOP is being developed by the University of Sheffield and partners as an open-source framework for creating digital twins. This provides a browser-based interface for the digital twin to:

- simplify usage for multi-disciplinary teams/organisations

- provide a common language to integrate with multiple systems

- demonstrate the “virtual representation” aspect of the digital twin concept

This project involves work done through multiple funding rounds from the Alan Turing Institute and the EPSRC funded programme grant Digital Twins for Improved Dynamic Design.

Gathering the data

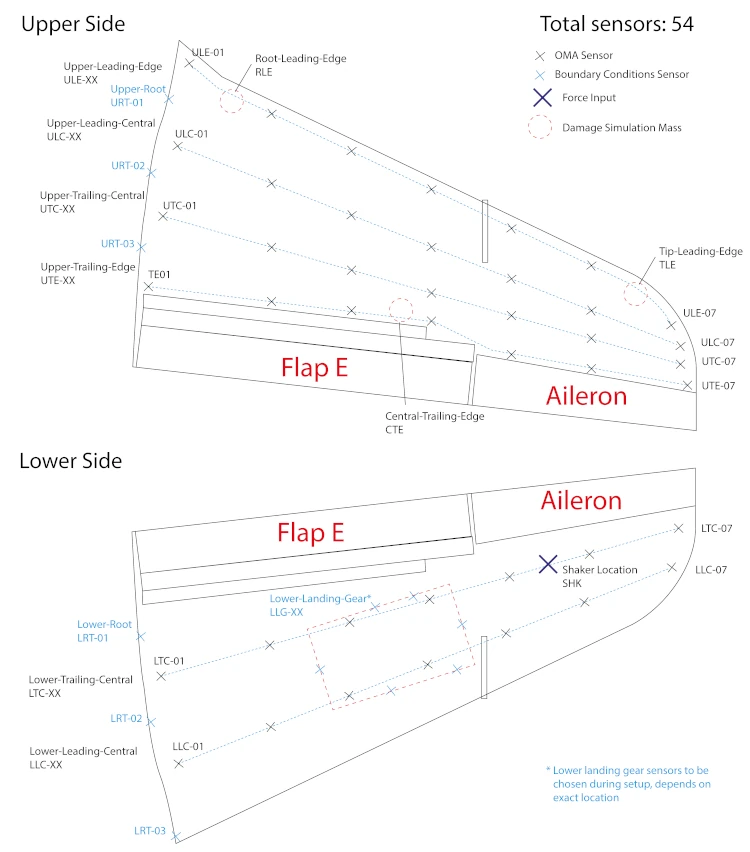

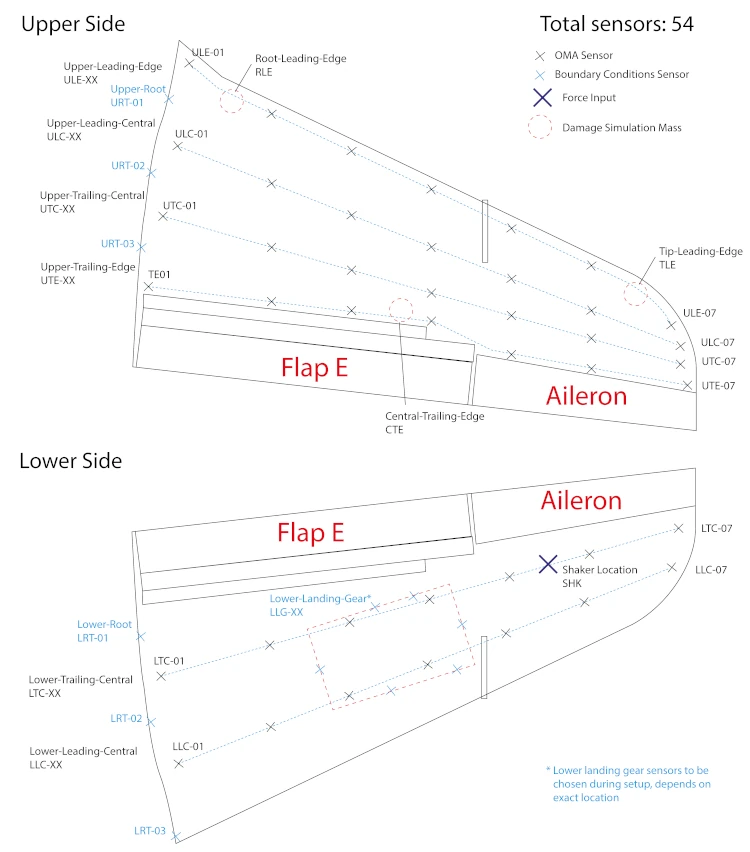

One of the main data sets collected during this project is structural data from the starboard wing in-situ. This testing included a variety of excitation profiles and approximately 55 accelerometers placed on both the top and bottom of the wing.

Diagram showing accelerometer arrangement

Diagram showing accelerometer arrangement

Accessing the data (ORDA database)

The data is publicly available via the ORDA database.

This data is stored in the open source HDF5 format and contains (for each accelerometer):

- time history

- auto power spectrum

- coherence

- dynamic stiffness

- frequency response function

- spectra

Each excitation in the database is repeated 10 times and stored in a singular HDF5 file. In addition to the HDF5 files, there is also a readme file for a better understanding of the data and an example Python script to load in these files into Python. There are two main methods for accessing the data: manual download and loading, and the developed python API (using python 3.9+). For the API, there is a light header file that is downloaded during the pip install that is designed to identify if there is a local version of the data downloaded to load, or automatically download only the required files from the database.

The system used for this project is a BAE T1A Hawk aircraft with tail number XX184. This aircraft has been gifted to The University of Sheffield from the Defence Science and Technology Laboratory in 2018, after being decommissioned from the Royal Air Force. During its time at the Royal Air Force, it flew at several air shows and memorials using multiple liveries (paint jobs).

Physical System

LVV Hawk T1A XX184 in Flight Credit: Mark Williamson

LVV Hawk T1A XX184 in Flight Credit: Mark Williamson

The Hawk was originally constructed in 1977 and de-registered in 2017. This aircraft type is a fixed-wing trainer jet. The body is made primarily of aluminium with a symmetric aerofoil design. During its time at the Royal Air Force, it was part of the 100 Squadron providing training and operational support. This system currently lives at the Laboratory for Verification and Validation.

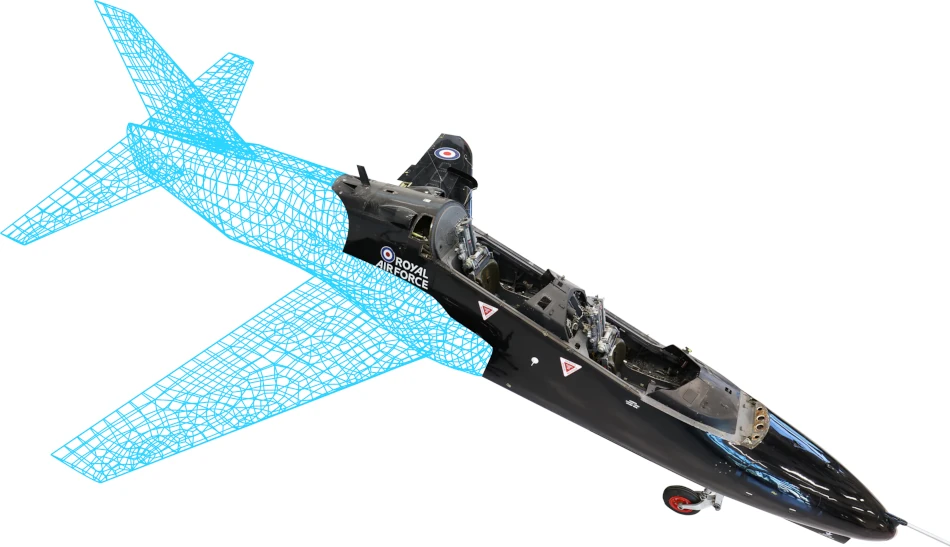

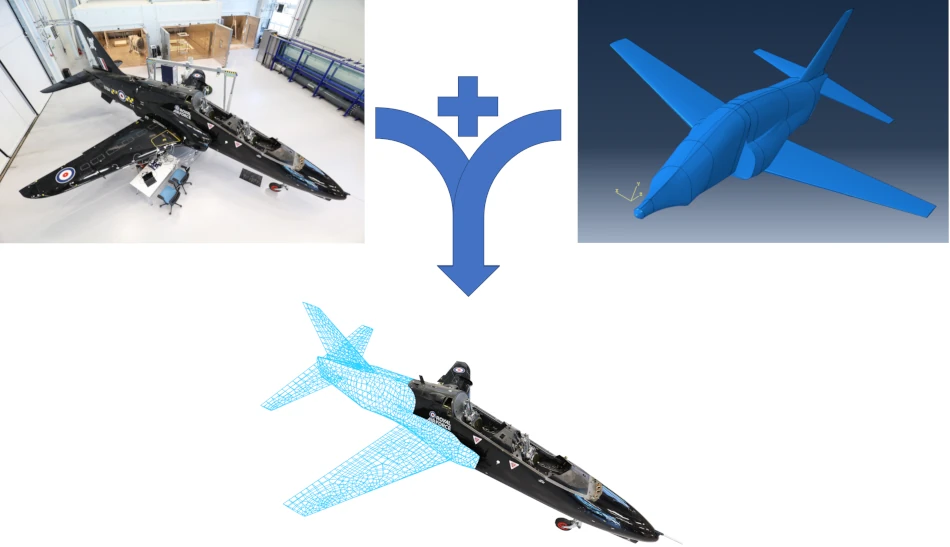

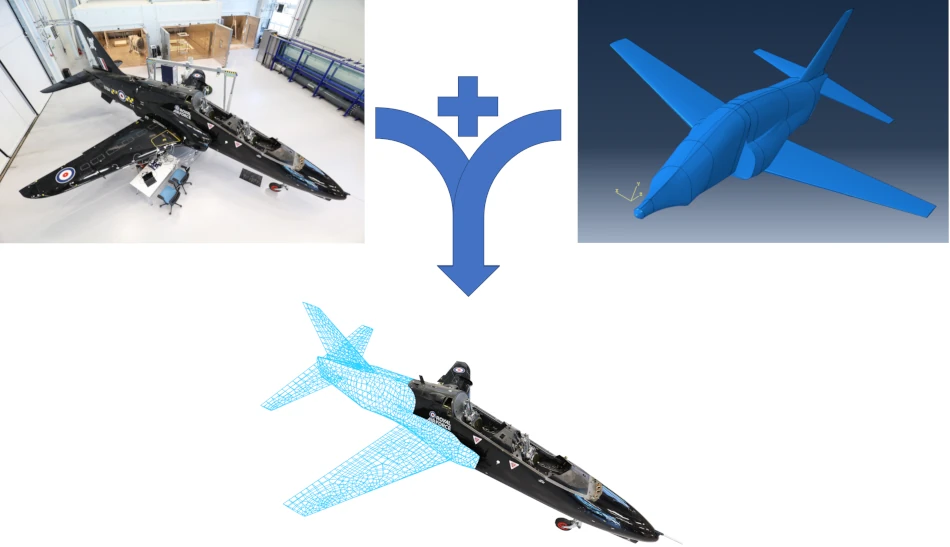

Virtual System

The virtual system (the Digital Twin) is a combination of multiple fidelities of 3D models, data informed models, and the collection of data gathered during testing. The 3D CAD models shown on this page are a graphic representation of the system. Since this system is a legacy system (originally developed before CAD-based design was common), this geometry has been generated using assembly blueprints via reverse engineering. An alternative option would be to 3D scan the system, which we plan to do in the current phase. In order to access this virtual system, an instance of the DTOP framework has been implemented to give access to users (both locally and remotely) through their browser.

This methodology has been published in peer-reviewed journals by the project Principal Investigators. This includes Development of DTOP Interface and Contextualisation of Information and Trust in a Digital Twin.

By implementing a Digital Twin Operational Platform, the virtual system is flexible enough to:

- contain multiple models

- provide multi-physics simulations

- ensure cyber-security

- use trusted commercial solutions

The purpose of this project is to demonstrate digital twin principals through the Digital Twin Operational Platform (DTOP) framework. DTOP is being developed by the University of Sheffield and partners as an open-source framework for creating digital twins. This provides a browser-based interface for the digital twin to:

- simplify usage for multi-disciplinary teams/organisations

- provide a common language to integrate with multiple systems

- demonstrate the “virtual representation” aspect of the digital twin concept

This project involves work done through multiple funding rounds from the Alan Turing Institute and the EPSRC funded programme grant Digital Twins for Improved Dynamic Design.

One of the main data sets collected during this project is structural data from the starboard wing in-situ. This testing included a variety of excitation profiles and approximately 55 accelerometers placed on both the top and bottom of the wing.

Accessing the data (ORDA database)

The data is publicly available via the ORDA database.

This data is stored in the open source HDF5 format and contains (for each accelerometer):

- time history

- auto power spectrum

- coherence

- dynamic stiffness

- frequency response function

- spectra

Each excitation in the database is repeated 10 times and stored in a singular HDF5 file. In addition to the HDF5 files, there is also a readme file for a better understanding of the data and an example Python script to load in these files into Python. There are two main methods for accessing the data: manual download and loading, and the developed python API (using python 3.9+). For the API, there is a light header file that is downloaded during the pip install that is designed to identify if there is a local version of the data downloaded to load, or automatically download only the required files from the database.

The system used for this project is a BAE T1A Hawk aircraft with tail number XX184. This aircraft has been gifted to The University of Sheffield from the Defence Science and Technology Laboratory in 2018, after being decommissioned from the Royal Air Force. During its time at the Royal Air Force, it flew at several air shows and memorials using multiple liveries (paint jobs).

Physical System

LVV Hawk T1A XX184 in Flight Credit: Mark Williamson

LVV Hawk T1A XX184 in Flight Credit: Mark Williamson

The Hawk was originally constructed in 1977 and de-registered in 2017. This aircraft type is a fixed-wing trainer jet. The body is made primarily of aluminium with a symmetric aerofoil design. During its time at the Royal Air Force, it was part of the 100 Squadron providing training and operational support. This system currently lives at the Laboratory for Verification and Validation.

Virtual System

The virtual system (the Digital Twin) is a combination of multiple fidelities of 3D models, data informed models, and the collection of data gathered during testing. The 3D CAD models shown on this page are a graphic representation of the system. Since this system is a legacy system (originally developed before CAD-based design was common), this geometry has been generated using assembly blueprints via reverse engineering. An alternative option would be to 3D scan the system, which we plan to do in the current phase. In order to access this virtual system, an instance of the DTOP framework has been implemented to give access to users (both locally and remotely) through their browser.

This methodology has been published in peer-reviewed journals by the project Principal Investigators. This includes Development of DTOP Interface and Contextualisation of Information and Trust in a Digital Twin.

By implementing a Digital Twin Operational Platform, the virtual system is flexible enough to:

- contain multiple models

- provide multi-physics simulations

- ensure cyber-security

- use trusted commercial solutions

The data is publicly available via the ORDA database.

This data is stored in the open source HDF5 format and contains (for each accelerometer):

- time history

- auto power spectrum

- coherence

- dynamic stiffness

- frequency response function

- spectra

Each excitation in the database is repeated 10 times and stored in a singular HDF5 file. In addition to the HDF5 files, there is also a readme file for a better understanding of the data and an example Python script to load in these files into Python. There are two main methods for accessing the data: manual download and loading, and the developed python API (using python 3.9+). For the API, there is a light header file that is downloaded during the pip install that is designed to identify if there is a local version of the data downloaded to load, or automatically download only the required files from the database.

The system used for this project is a BAE T1A Hawk aircraft with tail number XX184. This aircraft has been gifted to The University of Sheffield from the Defence Science and Technology Laboratory in 2018, after being decommissioned from the Royal Air Force. During its time at the Royal Air Force, it flew at several air shows and memorials using multiple liveries (paint jobs).

The Hawk was originally constructed in 1977 and de-registered in 2017. This aircraft type is a fixed-wing trainer jet. The body is made primarily of aluminium with a symmetric aerofoil design. During its time at the Royal Air Force, it was part of the 100 Squadron providing training and operational support. This system currently lives at the Laboratory for Verification and Validation.

Virtual System

The virtual system (the Digital Twin) is a combination of multiple fidelities of 3D models, data informed models, and the collection of data gathered during testing. The 3D CAD models shown on this page are a graphic representation of the system. Since this system is a legacy system (originally developed before CAD-based design was common), this geometry has been generated using assembly blueprints via reverse engineering. An alternative option would be to 3D scan the system, which we plan to do in the current phase. In order to access this virtual system, an instance of the DTOP framework has been implemented to give access to users (both locally and remotely) through their browser.

This methodology has been published in peer-reviewed journals by the project Principal Investigators. This includes Development of DTOP Interface and Contextualisation of Information and Trust in a Digital Twin.

By implementing a Digital Twin Operational Platform, the virtual system is flexible enough to:

- contain multiple models

- provide multi-physics simulations

- ensure cyber-security

- use trusted commercial solutions

The virtual system (the Digital Twin) is a combination of multiple fidelities of 3D models, data informed models, and the collection of data gathered during testing. The 3D CAD models shown on this page are a graphic representation of the system. Since this system is a legacy system (originally developed before CAD-based design was common), this geometry has been generated using assembly blueprints via reverse engineering. An alternative option would be to 3D scan the system, which we plan to do in the current phase. In order to access this virtual system, an instance of the DTOP framework has been implemented to give access to users (both locally and remotely) through their browser.

This methodology has been published in peer-reviewed journals by the project Principal Investigators. This includes Development of DTOP Interface and Contextualisation of Information and Trust in a Digital Twin.

By implementing a Digital Twin Operational Platform, the virtual system is flexible enough to:

- contain multiple models

- provide multi-physics simulations

- ensure cyber-security

- use trusted commercial solutions